Dualdocker

Innovative mooring solutions

for floating structures.

Comfort & Safety

- JERK-FREE

As a result incredibly calm position in wind and waves. This is essential comfort for floating houses.

No additonal dynamic forces are built up. These additional dynamic forces are often higher than the static forces from wind, waves and currents! - HIGH DAMPING CAPACITY

Wind & waves, currents & floating debris are dynamic forces and cause ‘kinetic energy’

This kinetic energy is gently absorbed by the DualDocker damper

- RETENTION FORCES

DualDocker reduces retention forces by up to 90%!

Reduced retention forces means:

Safety, minimal stress and lower construction costs!

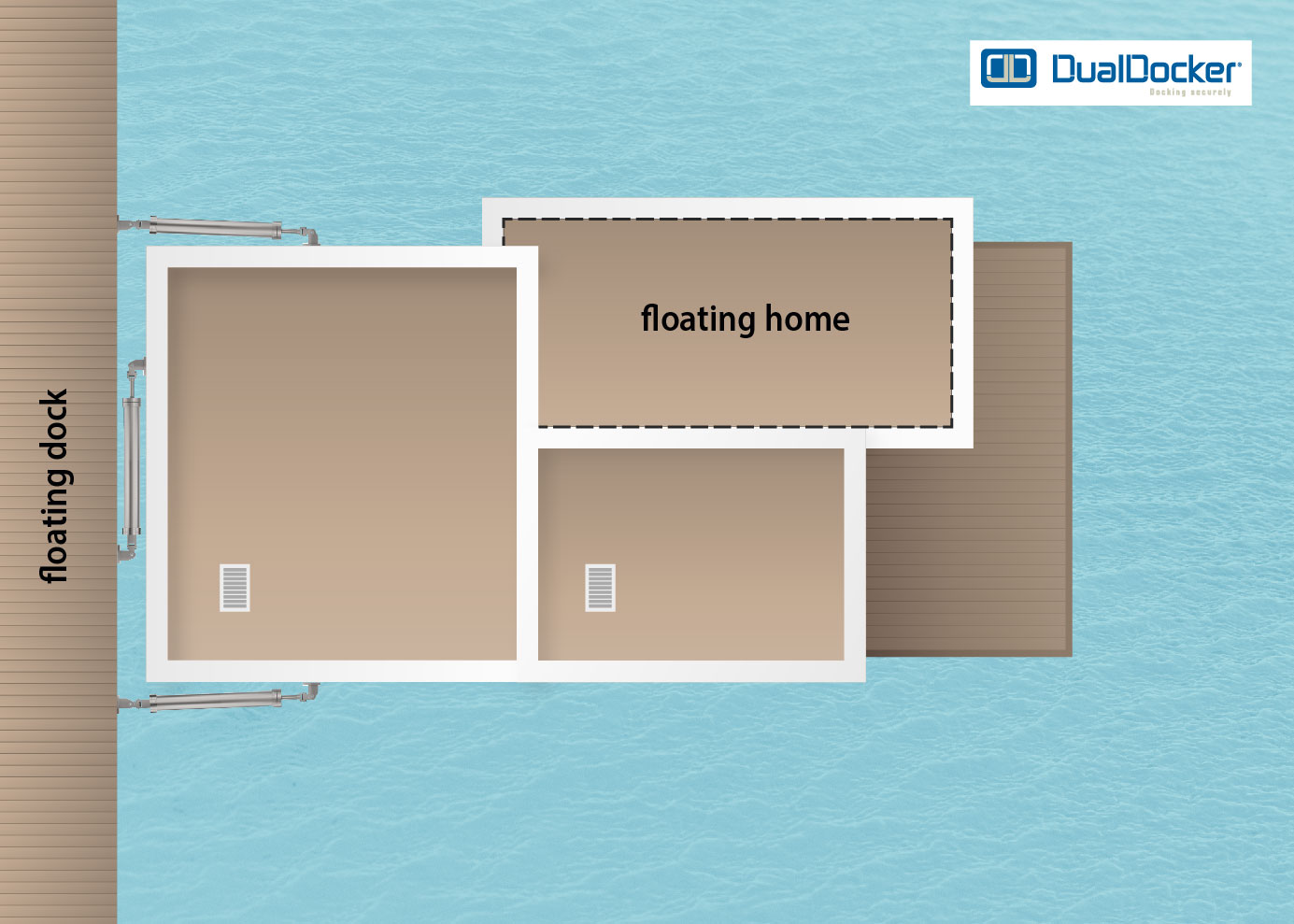

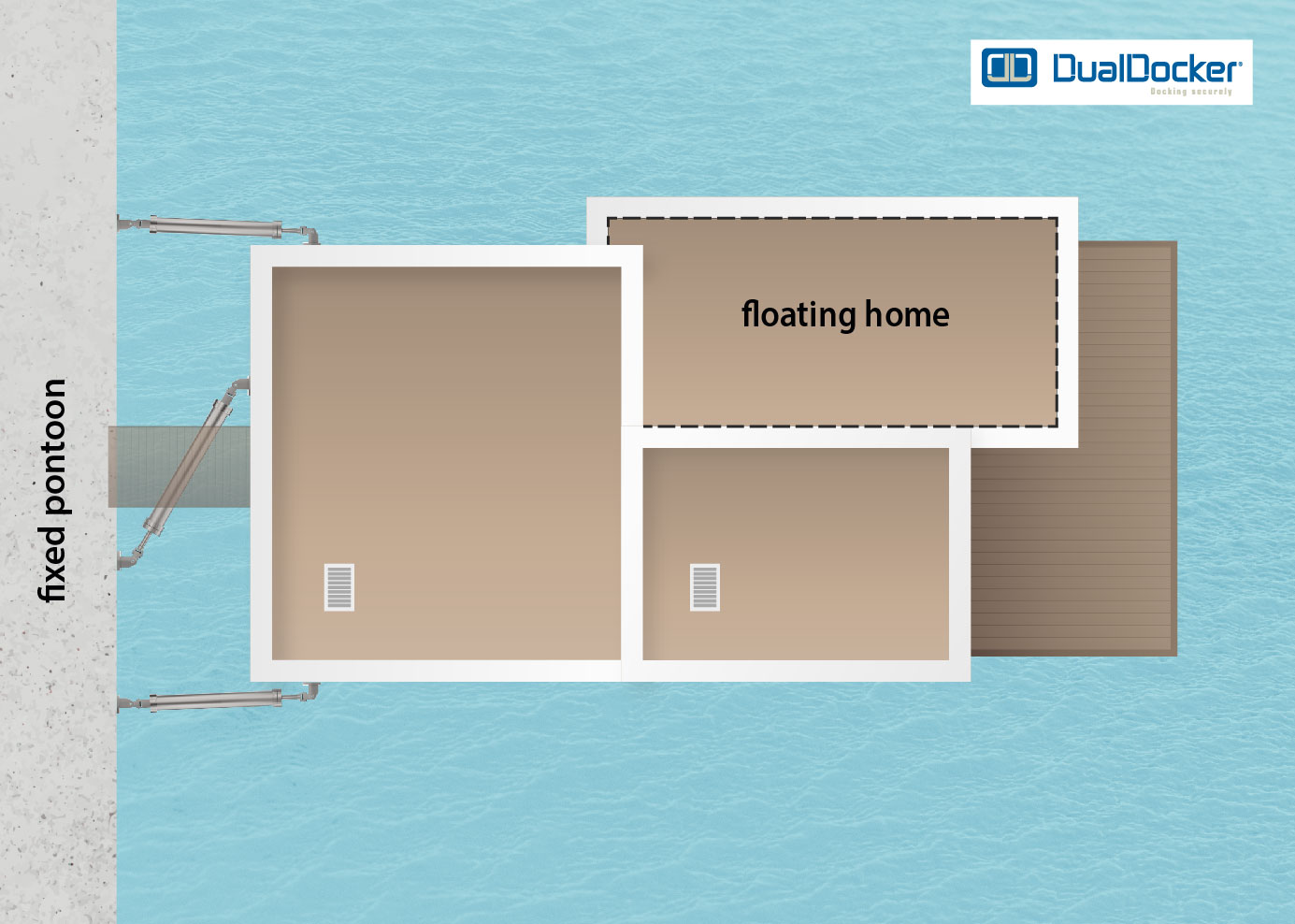

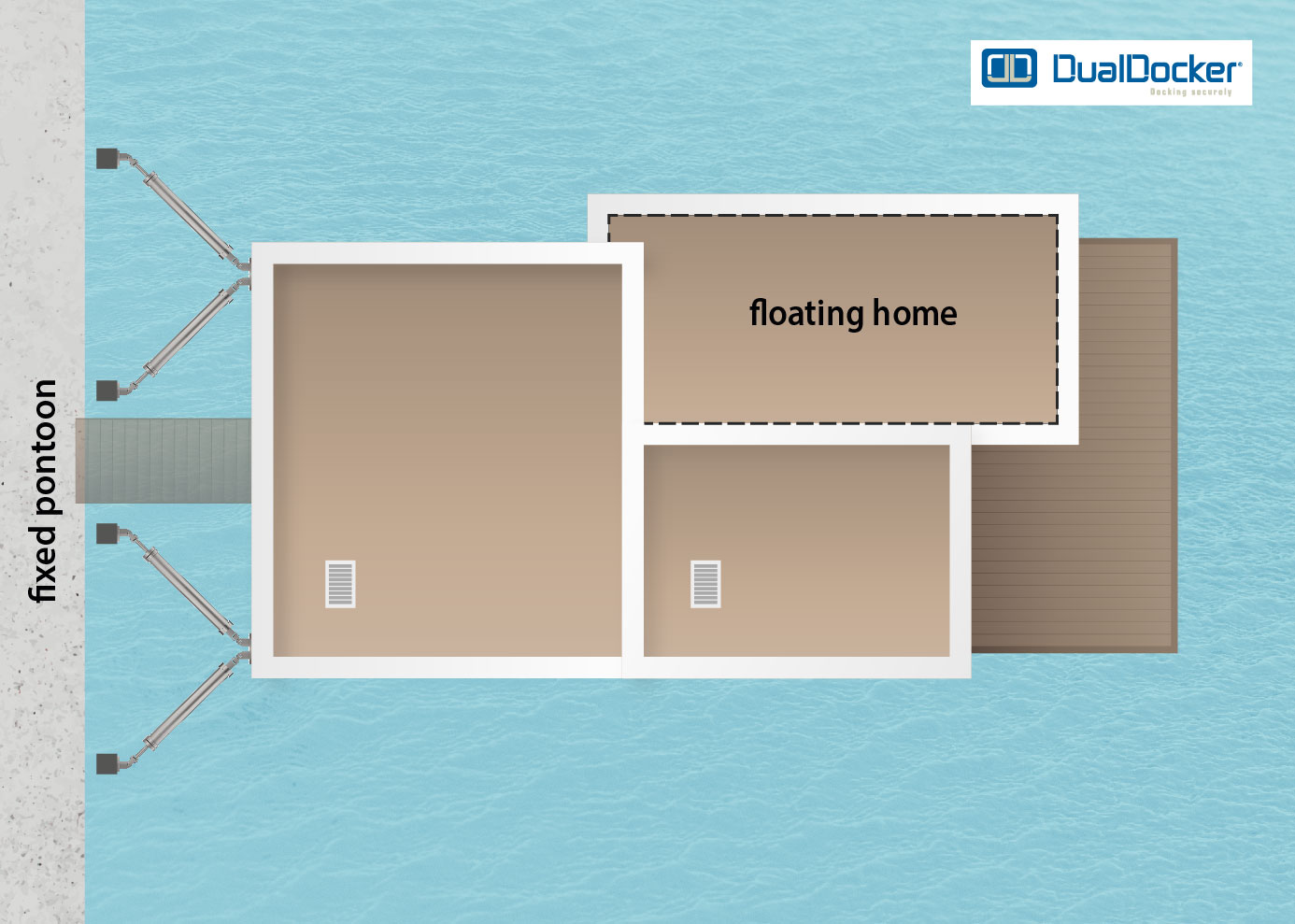

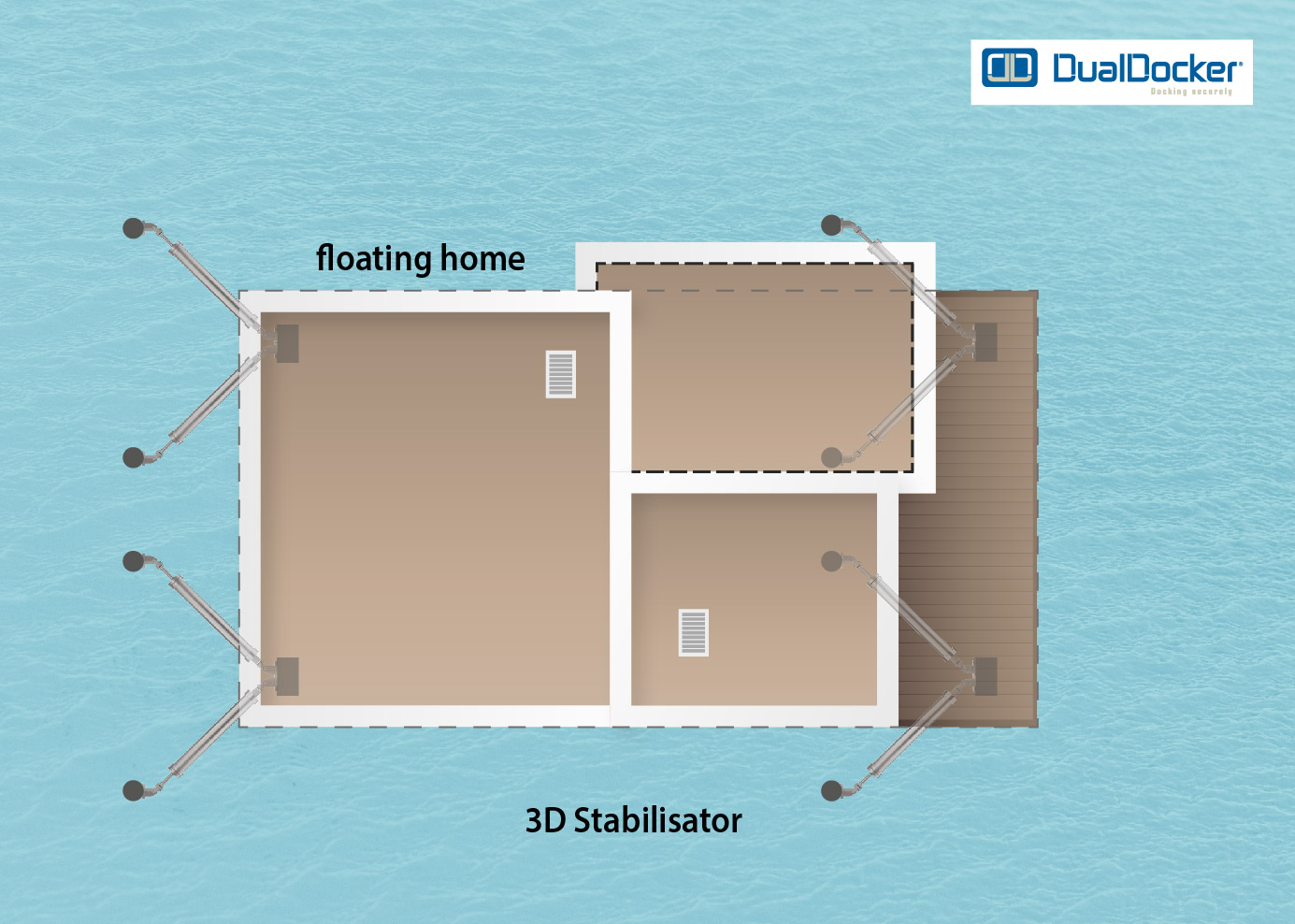

possible applications

Overview Mooring solutions

| Chain | Pile | DualDocker | |

|---|---|---|---|

| Damping Capacity | . | . | . |

| Retention Force | . | . | . |

| High Water Depth | . | . | . |

| Seabed Conditions (mud, rocks, etc.) | . | . | . |

| Environmental Impact | . | . | . |

Introduction:

Dualdocker are highly damped and play free cylinders between a floating structure and quaywalls, piles or other anchor points. Typically Dualdocker are installed above the waterline. If requried DualDockers can be installed also submerged.

Damping Capacity

DualDocker Arms have a high damping capacity Depending on your project requriements, we calculate the required damping capacity and set up.

Jerk-free:

DualDocker arm systems are free of play

Cost and Safety

DualDocker Systems provide highest safety.

- DualDocker Systems are free of play and prevent the build up of dynamic forces.

- DualDocker Systems are highly damped. Kinetic energy from wind & waves, a mooring maneuver, collision or flotsam are absorbed. The high damping capacity reduces the braking forces of up to 90%.

Comfort in wind and wave

Due to the high damping and no play the floating structure is calm and comfortable in wind and waves.

Environmental Impact:

Dualdocker Systems have no negative impact on the underwater environment.

Design:

DualDocker are well designed high end products of best quality.

Introduction:

Piles are loaded horizontally and introduce the horizontal forces into the subsoil.

Damping Capacity

Piles usually only have a low damping capacity (depending on material, diameter & wall thickness, lever arm and subsoil conditions).

Jerk-free:

When inserting piles, attention must be paid to the accuracy of both the position and the verticality so that the play in the pile guides is as low as possible. With eventual wear of the pile guides the play increases even more.

Cost and Safety

Cost and safety ist very dependent from the soil conditions (sand, mud, rock)

- Stone and rock cause high costs during construction

- High water depth and soft ground require large pile diameters and cause high costs

- During a mooring maneuver of a yacht the pile has to absorb the energy entirely. Due to the low damping capacity high impact force peaks are developed

Comfort in wind and wave

Due to the possible play in the pile and pile guides in wind and wave uncomfortable jerking may be experienced

Environmental Impact

Piles are a major disturbance to the seabed

Design

At low tide piles are often very visible as they can jut out several meters from the water surface. Steelpiles develop rust on the surface.

Introduction:

Chain systems use their own weight as holding forces (sag in the form of the catenoids) and the connection of the chain with the sea bed

by heavy concrete blocks or drilled ground anchors.

Damping Capacity

Chains have a 2-stage damping characteristic. Up to approx. 10% of the breaking load, the chain has good and slow damping due to its chain weight.

As from approximately 10% of the breakload the chain is stretched and as a result the damping capacity is only very low.

Jerk-free:

At the correct configuration chain systems are theoretically free of play. The chain length is to be dimensioned in such a way that it is sufficiently long in case of high water. However, the chain must not touch the seabed when the tide is low.

Limiting Factors:

Chain systems require lot of space. Chain system solutions at uneven ground conditions or low water depths are often difficult to realize.

Cost and Safety

Safety is at stake when:

a; when large static forces occur (stong currents, waves and/or storm)

b; when high dynamic forces have to be absorbed (kinetic energy from a mooring maneuver, collision, flotsam)

c; high and critical wave action

Comfort in wind and wave

At low tide chains are less tensioned. That can cause larger moveements and uncomfortable jerking in wind and waves

Environmental Impact

Chains are a major disturbance to the seabed as chains often touch the seabead and destroy the seaflora.

Introduction:

Stiff mooring arms are stiff connections between floating structures and quaywall. Therefore the anchoring on shoreside must be able to absorb the entire load of horizontal forces.

Damping Capacity

Stiff mooring Arms have no damping capacity

Jerk-free:

Stiff mooring arm systems are theoretically free of play. Joints and connections in practice have got little play. Diagonal lines stretch over time and create little play.

Limiting Factors:

When high dynamic forces have to be absorbed (kinetic energy from a mooring maneuver, collision, flotsam) extremely high braking forces are requried.

These systems should not be used in situations like described above.

Cost and Safety

Safety is at stake when:

a; when large static forces occur (stong currents, waves and/or storm)

b; when high dynamic forces have to be absorbed (kinetic energy from a mooring maneuver, collision, flotsam)

c; high and critical wave action

Comfort in wind and wave

Due to the lack of damping the floating structure can be uncomfortable in wind and waves, if little play is present in joints, connections or the diagonal lines the structure may jerk.